PSA Oxygen Plant

Maruti Suzuki boosting manufacturing of Oxygen PSA generator plants –

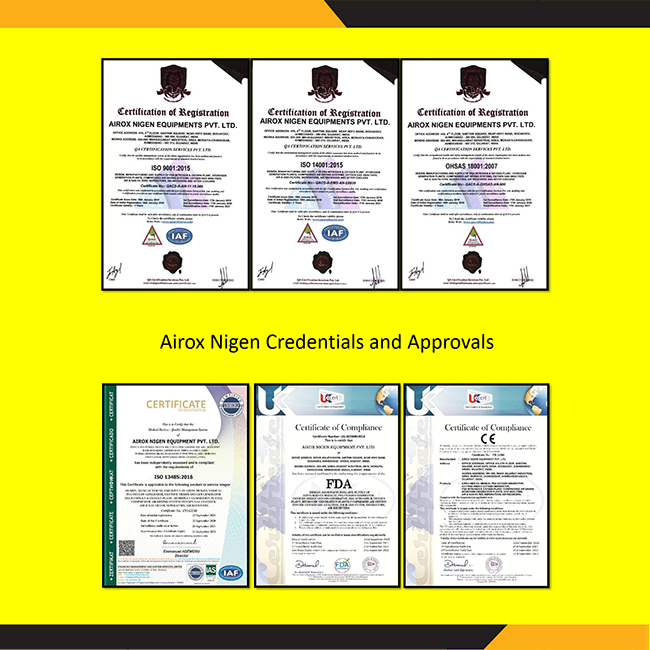

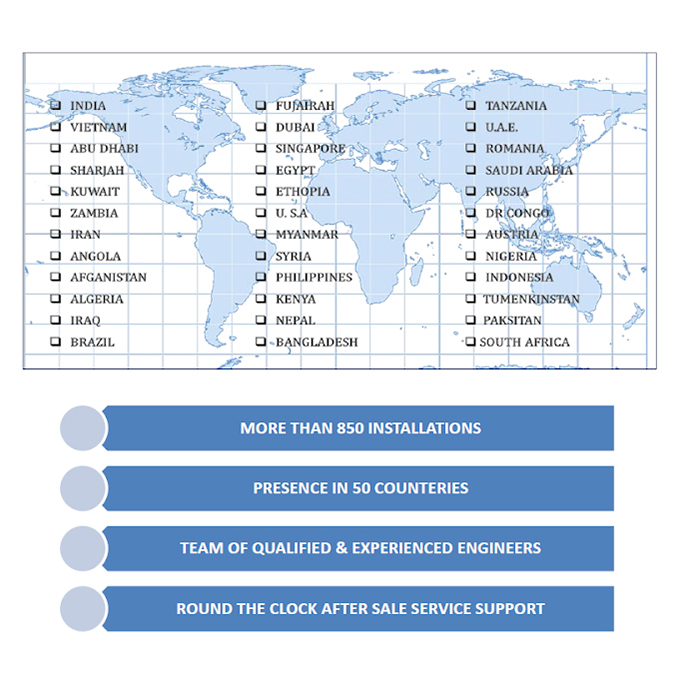

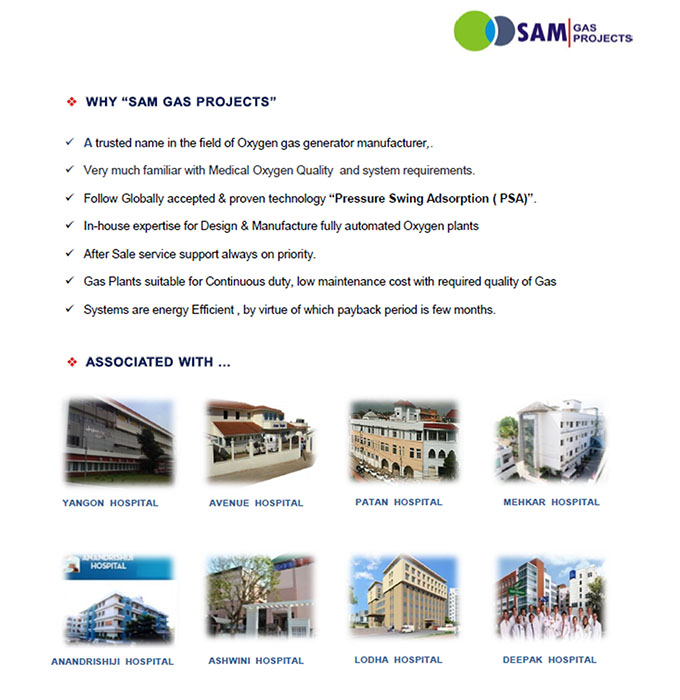

Maruti Suzuki India Ltd. (MSIL) realised the critical importance of rapidly installing Oxygen PSA plants, both to produce life-saving oxygen as well as reduce the immense logistical problems. It was found that these plants are being made by small scale units with very limited resources or ability to scale-up production. MSIL has located three companies namely M/s Airox Nigen Equipments Pvt Ltd, M/s SAM Gas Projects Pvt Ltd. and M/s Gaskon Engg. These companies are flooded with orders but have a capacity to manufacture only 6-8 plants a month. MSIL decided to use their resources to help scale-up their production.

For these PSA plants, while technology, quality and performance, as well as all commercial matters, would remain the responsibility of the two companies, MSIL and its vendors would use their capabilities to rapidly scale up production. MSIL’s involvement would be on a no profit basis. MSIL and its suppliers are currently working in the direction of scaling up the production for each of the abovementioned manufacturers from current levels of 6-8 plants per month to 50-60 plants per month.The progress is personally being monitored by MSIL top management.

Considering the huge waiting list with individual suppliers, this website is created to facilitate capturing the PSA plant requirements from interested parties. Such requirements would be channelize in such a way that the humanity needs can be served in the quickest possible time through allocation to each manufacturer considering the pending order list and their capability to serve these orders. The broad specification of each manufacturer is listed in the specification section.

Interested parties can drop in their queries along with requirement sheet in Contact Us section. After receipt of the query and allocation thereof, the technical as well as commercial discussions would be handled by the concerned manufacturer as mentioned above.

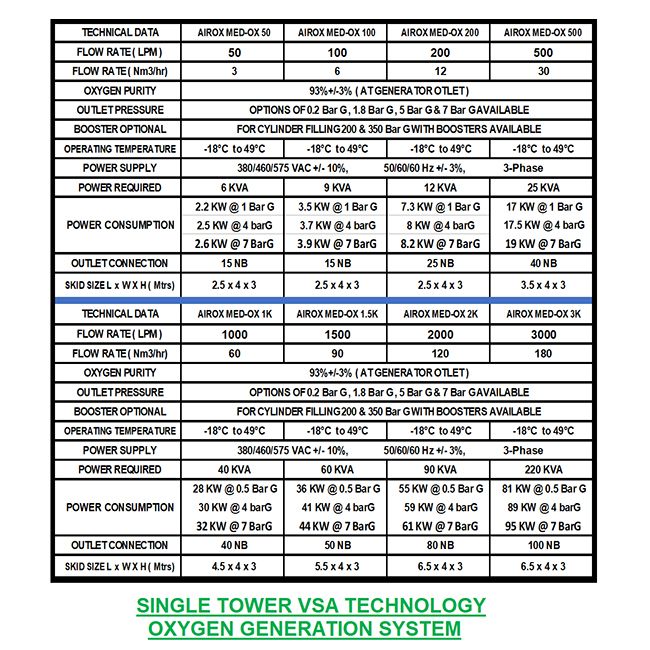

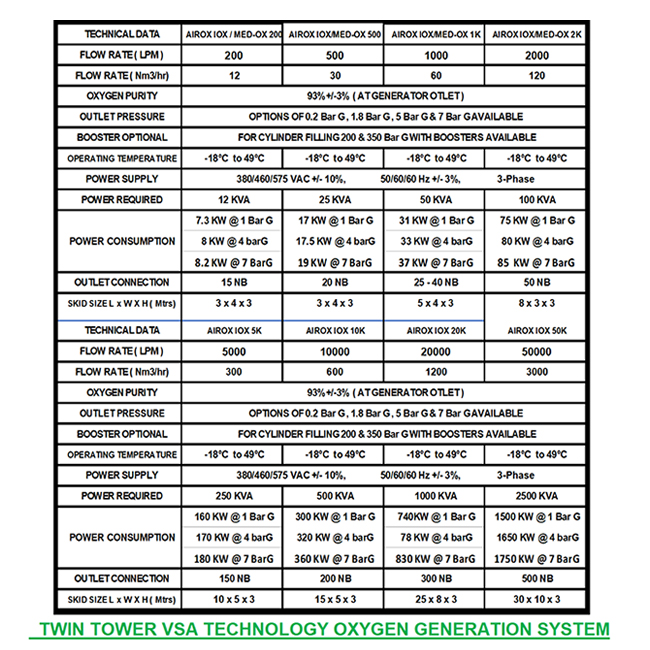

Specification

| S.No. | Capacity | No of Beds (Assumed flow rate @10LPM/patient) | Company Name | Equipment Dimensions (L X W X H) (in metres) | Floor Area Required including maintenance (L+2) X (W+2) (in metres) | Install-ation time (days) | Power Requirement | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in m3 / hr | in LPM (litres per min) | in kg / hr | in tons / day @24 hrs | Compressor (3-Phase) | Air Dryer (3-Phase) | Other Equipment (1-Phase) | ||||||

| 1 | 10 | 167 | 14 | 0.34 | 17 | Sam Gas | 5 X 3 X 4 | 7 X 5 | 2-3 | 22 kW, 36 A | 0.5 kW, 0.8 A | 0.5 kW, 3 A |

| 2 | 15 | 250 | 21 | 0.51 | 25 | 6 X 4 X 5 | 8 X 6 | 2-3 | 30 kW, 49 A | 1.0 kW, 1.6 A | 0.5 kW, 3 A | |

| 3 | 30 | 500 | 43 | 1.03 | 50 | 8 X 4 X 5 | 10 X 6 | 2-3 | 55 kW, 90 A | 1.5 kW, 2.4 A | 0.5 kW, 3 A | |

| 4 | 45 | 750 | 64 | 1.54 | 75 | 10 X 4 X 5 | 12 X 6 | 2-3 | 75 kW, 123 A | 2.0 kW, 3.3 A | 0.5 kW, 3 A | |

| 5 | 60 | 1000 | 86 | 2.06 | 100 | 12 X 4 X 5 | 14 X 6 | 2-3 | 90 kW, 148 A | 2.0 kW, 3.3 A | 0.5 kW, 3 A | |

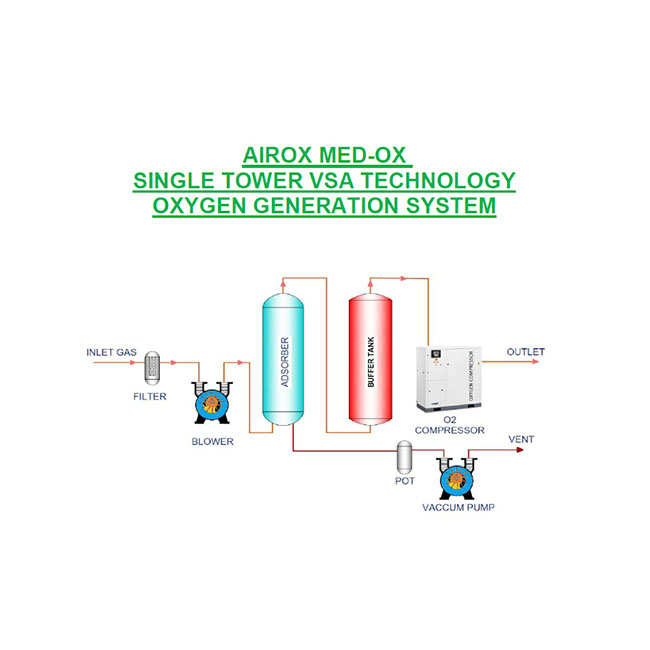

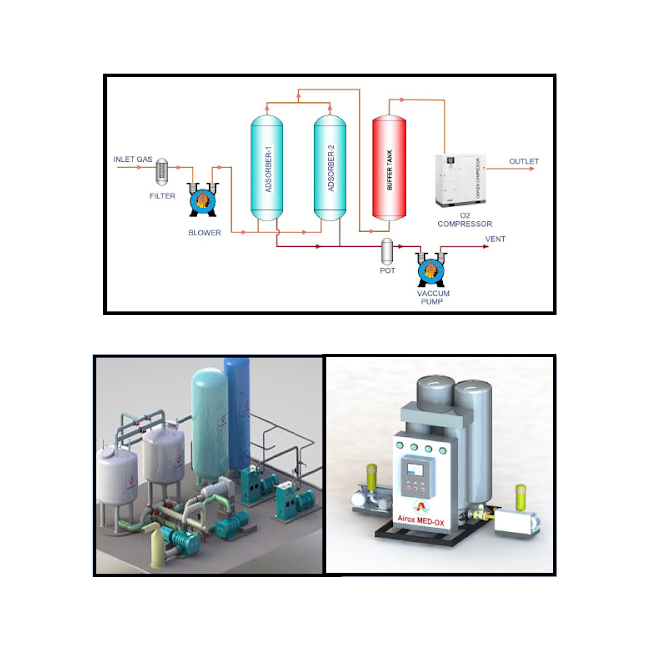

| 1 | 6 | 100 | 9 | 0.21 | 10 | Airox Nigen | 3 X 4 X 3 | 5 X 6 | 2-3 | 7.5 kW, 13 A | 1.5 kW, 2.5 A | 0.5 kW, 3 A |

| 2 | 15 | 250 | 21 | 0.51 | 25 | 3 X 4 X 3 | 5 X 6 | 2-3 | 22 kW, 36 A | 2 kW, 3.3 A | 0.5 kW, 3 A | |

| 3 | 30 | 500 | 43 | 1.03 | 50 | 5 X 4 X 3 | 7 X 6 | 2-3 | 45 kW, 74 A | 3 kW, 4.9 A | 0.5 kW, 3 A | |

| 4 | 45 | 750 | 64 | 1.54 | 75 | 6 X 4 X 3 | 8 X 6 | 2-3 | 75 kW, 123 A | 4 kW, 6.6 A | 0.5 kW, 3 A | |

| 5 | 60 | 1000 | 86 | 2.03 | 100 | 10 X 4 X 3 | 12 X 6 | 2-3 | 90 kW, 148 A | 5 kW, 8.2 A | 0.5 kW, 3 A | |

| 1 | 6 | 100 | 9 | 0.21 | 10 | Gaskon Engineers | 5.5 X 3 X 4 | 7.5 X 5 | 2-3 | 11 kW, 20 A | 3.0 kW, 6 A | 0.5 kW, 3 A |

| 2 | 15 | 250 | 21 | 0.51 | 25 | 7.5 X 3 X 4 | 10 X 5 | 2-3 | 22 kW, 36 A | 3.0 kW, 6 A | 0.5 kW, 3 A | |

| 3 | 30 | 500 | 43 | 1.03 | 50 | 10 x 2.5 x4 | 12x4.5 | 2-3 | 45 kW 80A | 5.0 kW, 10A | 0.5 kW, 3 A | |

|

||||||||||||